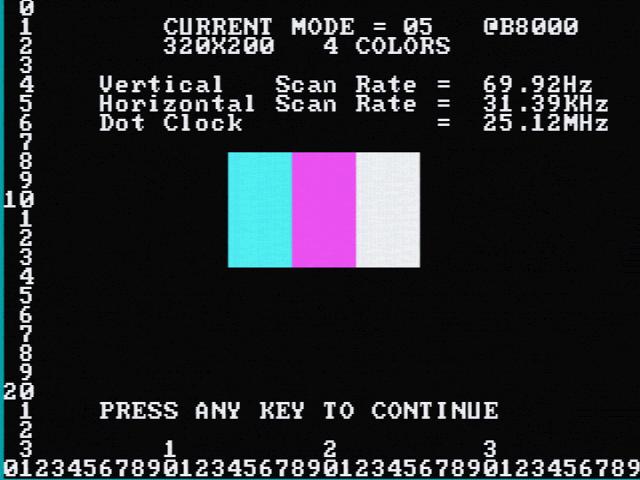

Progress is still being made on the exact modifications to be made to the video bios to get perfect picture in all video modes, so in parallel I am working to finialize the flashing patch so removal of the flash chip for programming is not required.

Currently to enable Vpp 12V for programming (pin11) I need to execute a sequence of read/writes to i/o addresses FC23h, F023h, C023h, 23h, 24h, 25h. The sequence was determined from disassembly of xpatch.exe

Update:

So the initial instructions on 23h do in fact seem to be an unlock sequence, and 24h,25h appear to be index and data registers. I had this feeling as xpatch was reading the values but doing nothing with them, so I started searching for the values with “unlock”.

https://patents.google.com/patent/US5630052

The above patent document basically confirms the concept of four consecutive reads, to FC23,F023,C023,23 to unlock/enter a configuration type command. So this is some progress, it is good to know these do not have any special meaning. This may be common knowledge people who work on these systems often.

So this leaves to do more investigation on the 24/25 index/data registers, and actually to understand what is this even commanding, the VLSI chip or the CPU. I am in the process removing the BGA packages from a board and tracing the wires out.

I want to understand their exact purpose of each register and not “guess”, however the datasheet for the VL82C420FC5 “SCAMP” (Single Chip At Mid Performance) is not available so I continue to read similiar datasheets for individual VLSI components to understand the methodologies and interfaces.