Here is a brief overview of some of the tools and methods I used for creating the board and for the ongoing development.

February 2026 Update 3

In the case of ISA-card projects, you can mostly assume you will be in a x86 PC and therefor trust that the user can run your configuration utility whether it is a standalone program or an option rom.

For PCMCIA however, the host machine could be many different architectures and an even wider range of operating systems. I previously demonstrated the onboard web-server that can be used, however not all platforms will support this and not everyone is even interested in networking.

A few things you may find yourself needing to change:

- Wi-Fi Settings

- Bluetooth Pairing (Gamepads and Mice)

- Card Mode (Network Adapter, SRAM, Etc)

- Audio DSP Parameters

These are the current methods for managing the card, all at varying stages:

- Webpage via Emulated NE2000

- AT commands via emulated COM/Serial Port

- MS-DOS utility

- External USB CDC Emulated Modem (And Web Browser)

- External USB Emulated Storage

- Config File

The above video shows off the concept of managing it via AT commands which is even more universal than NE2000.

February 2026 Update 2

Small follow-up to the previous update. I’ve now also finished the Bluetooth mouse support. This would also work with a USB mouse, in either case they are presented to the host as a serial mouse attached to a COM port so support should be universal.

February 2026 Update 1

Bluetooth Gamepads / Joysticks

I had planned this for a while and have finally got to it. It is working quite well. A2DP Bluetooth audio for wireless headphones also works but I will provide an update on that later. USB wired gamepads are still supported also (Thank PicoGUS!).

Wireless / Formfactor

A flush antenna worked technically but created even bigger compliance complications, so the plan now is to use the pre-certified Raspberry Pi RM2 radio module instead.

Initially I was not using the Raspberry Pi RM2 module as it did not exist when I started this project, and once it was announced I found the width was not compatible. Since then I switched to the HRS I/O connector which is narrow and saved space, and I have switched from a “Push-Push” to “Push-Pull” SDCard socket to also save some width, allowing the RM2 module to JUST fit. Downside is we are back to having a 5.2mm (just under 1/4″) PCB trace antenna sticking out, but the plus side we will have even better wireless reception.

I am waiting on PCB’s and I should have prototype to confirm no unexpected issue within the next week. It uses the exact same CYW43439 radio so not expecting problems.

Compliance / Certifications

I have a booking with the laboratory to do a day of pre-compliance testing for FCC Part 15 and related, as well as further testing/review on exposure limits and additional SAR tests to be in compliance as a portable device.

Some people ask me why I am so worried about compliance testing, and there are two sides to it.

No question this is an extremely low volume product/project, and although I did mention this is intended for development purposes, standing on that argument for an exemption is not very strong at best.

More importantly, unlike a lot of hobby projects where it is a card stuck in an old computer you turn on in your basement, this is a PCMCIA card that will be in laptops/pda’s etc and many of them will find themselves in public locations where it is more important they do not cause any interference or exceed any RF exposure limits.

Current Timeline / Plan

I have already purchase all of the components required that are in short supply and/or discontinued, so the risk of any delay due to supply chain is very low.

The boards I will receive next week (February 9th) should be very close to the final design. I have all the parts needed to build the prototypes and provided there are no issues I will be sending them out to various people for testing/review.

I expect some minor changes (mechanical,compliance), and plan to make a small batch of cards integrating those changes at the end of the month once the PCB factories come back from Holiday and get through their backlogs. If there are no issues with end-users on those cards I will gear up make the large batch of remaining cards.

Internal Audio

This is a quick demo using a feature of PCMCIA, allowing low quality audio to be fed directly to the computers PC Speaker. This was intended for modems to be able to output sound for dialing and connecting but there are a few soundcards that had this ability.

In the following list you can see some cards with the note “Outputs to PC Speaker). Soundcard List – GoogleSheet

The quality will vary between systems depending on how they implemented the internal audio. We will be able to use the EQ on the DSP to try and further optimize the output to get the best possible quality between systems.

Breakout Update

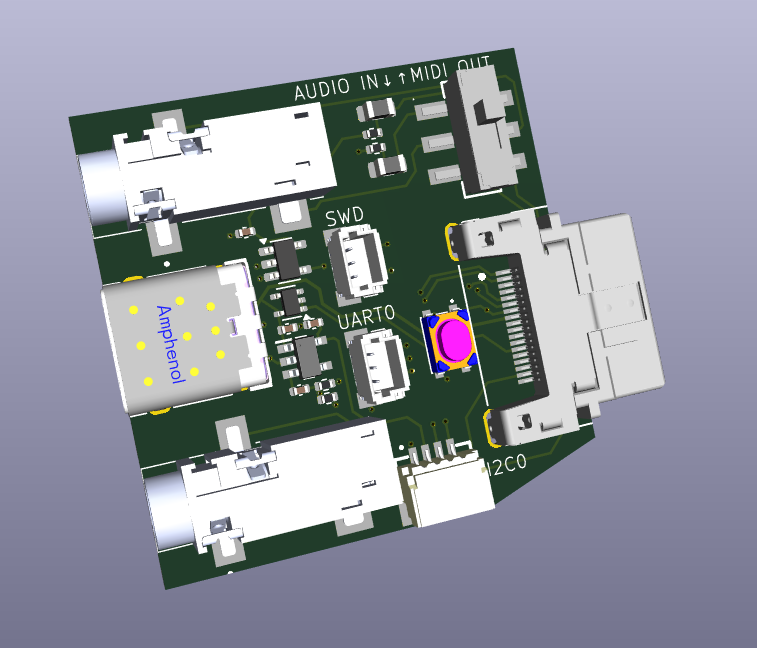

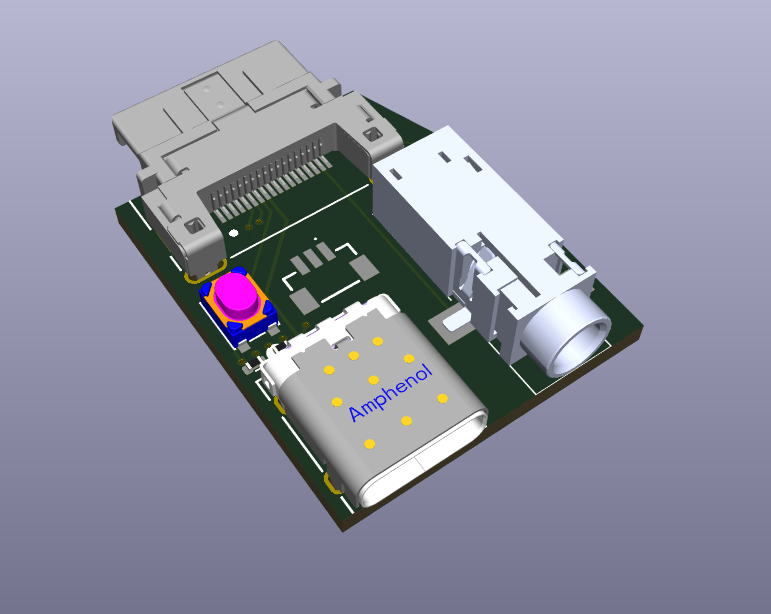

Here is the initial breakout board. It got a bit bigger than I had planned, but I wanted to get every function included out of the box. You can then make your own cables specialized to specific uses if you want something compact.

I also would like to modify this 3d print so that it extends out further, and it could be used in the slot below (where available) to support the breakout board and prevent it bending down.

I still plan to make some specific use cables i.e. audio only, and you can still make your own cables very easy as the connectors are stocked everywhere.

Breakout Board V1

- 3.5mm amplified headphone output

- 3.5mm type-a midi output or audio line-in for mixing in dsp.

- USB-C connector (USB 1.1 from RP2354) for Programming or OTG cable with mouse or gamepad/joystick.

- 3pin JST-SH for SWD of RP2354

- 3pin JST-SH for UART0 or I2C1

- 4pin JST-SH for QWIIC (I2C0 + 3.3V)

Networking Update

There are several ways to use the PicoPCMCIA for networking and I will go into detail on this in another update, but here I want to focus on something new I added, a basic onboard router.

The Issue

The PicoPCMCIA emulates an NE2000 network adapter, giving it near-universal support. Almost any device with a PCMCIA socket that supports networking already has NE2000 drivers available. The tradeoff is that the host sees it as a wired connection and has no awareness of Wi-Fi settings like SSID or key. To configure wireless, you must either use a custom utility on the target system or manually edit a configuration file on the SD card.

An excellent example of such a custom utility for a similiar scenerio (BlueSCSI DynaPort), is the “BlueSCSI Desk Accessory” written by Joshua Stein.

I hope to (or somebody will) adapt this to work with the PicoPCMCIA card for use with Macs, but that leaves many other platforms so for day 1 I needed a more universal solution beyond the DOS utility I will include.

The “Solution”

I’ve added a rudimentary onboard router to the PicoPCMCIA card.

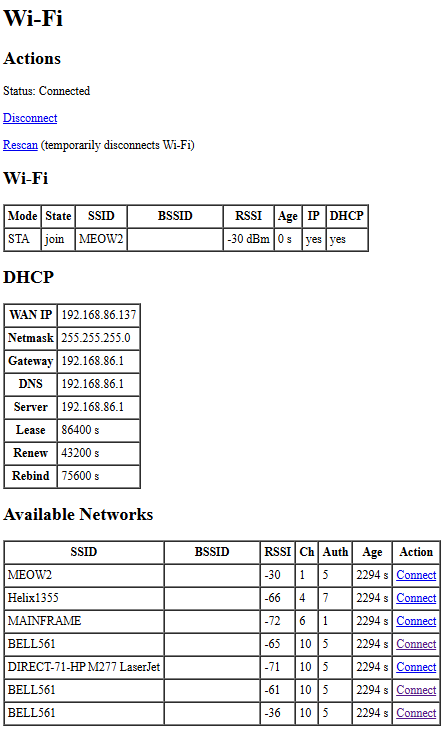

On power-up, it automatically (if enabled) attempts to reconnect to the last used SSID. The host system (your PC/PDA) is always assigned a fixed IP address of 192.168.1.100, even if Wi-Fi has not yet connected. This is especially useful for operating systems without DHCP support, as the address can be statically configured.

A simple management interface is available at h t t p://192.168.1.1/wifi. It uses a very basic HTML page designed to work with virtually any web browser. From there you can view the connection status, see what networks are available and attempt to connect. As this is the Pico doing the connection this of course can be any 802.11/b/g/n 2.4GHz network WPA/WPA2/WPA3 regardless what your computer/os is aware of.

Once Wi-Fi is connected, the host has IP network access through NAT routing, and WAN status is displayed on the management page. NAT also allows simultaneous use of Wi-Fi by both the host and the Pico itself, enabling additional features such as time synchronization or outbound connections from the emulated modem.

One point I would like to address is a way for devices using very simple browsers to be able to navigate through potential captive portals on public wi-fi’s. This will require some offloading of SSL etc. For another day.

Current Interface

This is simple HTML and can be improved easily, this is the bare minimum to get things going.

Breakout Board

If you are looking to reserve a card in the upcoming batch see here: https://www.yyzkevin.com/picopcmcia/reservation/

I selected the 18pin HRS connector as in the end it was the best way to get as many signals out of the card in such a small space, as we need the rest of the card edge for the SDCard and Antenna.

I had planned to include various cables with each card, but reality set in once I got quotes on custom cable assembly in low volumes.

I will provide some cable choices as options for an added cost. I will also offer the unsoldered connectors for those who wish to make their own cables, I will buy a bunch at once so it will be a bit cheaper than you buying your own from Digi-Key/Mouser and will save on shipping.

While contemplating this cost issue Kaede mentioned interest in making a PCB breakout board for development and it reminded me of these IBM/Xircom “rigid” dongles, which is the answer to the problem. A simple breakout board can be assembled much cheaper than a hand soldered cable and can provide all the basic features needed.

I’ve placed the Breakout into its own repository and I am working out the final details on it. Any feedback on features you would like to be included on this breakout would be appreciated.

Limitations / Constraints

- Must not be wider that 14mm from the center of the connector on the right hand side to ensure it can fit onto cards in some confined spaces.

- Can go wider on the left side but will obstruct the MicroSD. This should be okay as it is not intended to be hot swap.

- Want to keep the size as small as possible for convenience but also to minimize leverage and damaging the connector.

Planned Connections

- USB-C (For programming and OTG peripherals)

- BOOTSEL Button (For programming)

- 3.5mm Headphone Jack (Amplified)

- 3pin JST-SH for RP2354 SWD

- 2.5mm MIDI OUT (not added yet)

If the budget can permit, a 3D printed clamshell to give it a finished look will be nice.

Example Rendering

Current Pinout

Pinout

| Pin | Signal | Notes |

|---|---|---|

| 1 | SWCLK | RP2354 Serial Wire Debug (SWD) |

| 2 | SWDIO | RP2354 Serial Wire Debug (SWD) |

| 3 | GPIO34 | User I/O: GPIO, UART0 TX, or I²C1 SDA |

| 4 | GPIO35 | User I/O: GPIO, UART0 RX, or I²C1 SCL |

| 5 | USB D− | RP2354 USB Port |

| 6 | USB D+ | RP2354 USB Port |

| 7 | BOOTSEL | Boot select (firmware flashing / recovery) |

| 8 | 5V | 5 V from PC bus (350 mA fused) |

| 9 | GND | Ground |

| 10 | I2C0 SDA | I²C master (onboard DSP + external peripherals) |

| 11 | I2C0 SCL | I²C master (onboard DSP + external peripherals) |

| 12 | — | Not connected (Yet) |

| 13 | GPIO26 | UART1 TX (also internally connected to SAM2695 MIDI RX) |

| 14 | IN1_L | Line-in left (to DSP) |

| 15 | IN1_R | Line-in right (to DSP) |

| 16 | HPL | Headphones out left (from DSP) |

| 17 | HPR | Headphones out right (from DSP) |

| 18 | GND | Ground |

Connectors

The PicoPCMCIA External I/O uses Hirose ST-series connectors, chosen for their compact size and robust locking mechanism.

🔗 Hirose ST Series:

https://www.hirose.com/en/product/series/ST

Connector Part Numbers

| Description | Part Number |

|---|---|

| Card Receptacle | ST60-18P(30) |

| Breakout Plug | ST60X-18S(30) |

| Cable Plug Assembly | ST40X-18S-CV(30) |

| Cable Bushing | ST40X-BS(4.0) |

| Cable Clamp (4 mm) | ST40X-CM |

Pico PCMCIA

I have been slow to update the website but progress has been ongoing on the Pico PCMCIA project and I am now very close to producing the card. Much more compatibility testing has been done (I have been posting videos on youtube), and additional features have been implemented such as the CD-ROM emulation.

I will be posting further updates this week and will soon be opening up a pre-order form, but in the mean time if you are interested in receiving one of these cards, please fill out the following form to show your interest:

https://docs.google.com/forms/d/1r-MzxJfKxwGb2maxOPMMbPFBHwphOFvUf5JFLzJSLbA

The following video is an informal introduction/recap to some of the capabilities:

PCMCIA Pico W Card

My fascination with PCMCIA cards was created out of “necessity”. Most of my retro computing interest revolves around networking, and I wanted something that could natively attach to modern Wifi networks without the need to maintain an old linksys router just for my retro computers. There are many ways to do this, I just wanted something as clean and compact as possible. I was also left out of being able to use the various ESP based wifi modems as I mainly use an IBM PC110 and it has no serial port without a dock.

At the start I looked at butchering existing ethernet cards and wiring in a wifi232 module coupling together the ethernet PHYs. This was very sketchy and the module was large, no real hope of scaling it down.

I quickly moved onto attempting to make my own entire card. I used a small GAL for some address decoding, a parallel UART chip and a flash chip along side the esp8266. This worked quite well and depending on the crystal selected, when having the divisor at 0 (usually 115200 baud) it would actually be 460800. It was quite feasible to fit this onto a board in a tiny case, but the speed limitations and it only being a serial interface always had me thinking about an ethernet interface instead of or in addition to the UART. I did play with SLIP and various ways to use the serial interface to get onto the LAN, but it was not fast enough or transparent enough for what I wanted.

I came back to trying to emulate an NE2000 card on the ESP8266 (also tried ESP32). It was just too slow though, the interrupt latency on the ESP was already almost my entire 12uS time limit for an I/O cycle, and because of the limited IO on the all the ESP’s I needed to use an I/O expander chip or external multiplexer, and in both cases it was just so slow there was no chance. I even played with using a dual-port sram to act as a place to store the CIS on boot and to simulate the registers but there was just no overcoming how slow the ESP was in handling interrupts and manipulating the external multiplexer or expander. Maybe there were some other approaches but I put this back on to the back burner.

Then I saw the work by Ian Scott on the PicoGUS that was using a Rasberry Pi Pico to talk to an ISA bus. This brought the Pico to my attention and I quickly connected one to the PCMCIA bus to play around. I quickly saw that the interrupt latency for the PIO was very low, and the PIO itself allowed some very fast and easy coordination of the I/O wait signals and other potential multiplexing and that is how I arrived where I am at now.

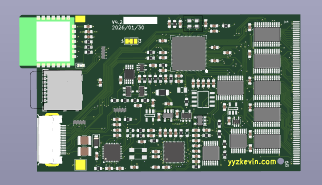

It is a very simple design. I use a CPLD to handle some of the “glue logic”, and to deal with the multiplexing, and it has the added benefit of having 3.3V I/O which is compatible with the Pico, but the I/O is also 5V tolerant which is compatible with the PCMCIA bus.

Next steps, I would like to encapsulate it into a card much like the legacy wifi cards. There will be some bonus functionality available through the USB port operating in host mode.

And depending on mechanical limitations perhaps an audio jack. That may get left to a larger version of the card with more functionality in the future. With the Pico there are so many possibilities.